Carbon Fiber Fabric

ACTEX offers a series of high performance carbon fiber fabrics, expertly woven from globally sourced premium fibers. Available in diverse weaves, weights, and widths, we also engineer bespoke solutions precisely tailored to your unique application.

- Home

- Carbon Fiber Fabric

Our Carbon Fiber Fabric Selection

It seems we can't find what you're looking for.

Actex's Comprehensive Carbon Fiber Weaving Capabilities

According to its weaving structure, common types of carbon fiber fabrics include plain weave, twill weave, satin weave and non-crimp fabrics. Different weaving methods give fabrics different characteristics, making them different in flexibility, molding difficulty, appearance and mechanical properties of the final product, so as to better meet the needs of various usage scenarios.

Actex provides common weaving processes and special customized weaving services, and supports flexible customization of weight and size to meet your diverse application needs.

Plain Weave

Structural features: Each warp and weft yarn are interlaced once (once up and down), with high density.

-

Advantages:

-

Good stability, not easy to deform

-

Smooth surface

-

Not easy to loosen when cutting

-

-

Application: Parts that require stable dimensions, appearance parts with high requirements for surface beauty.

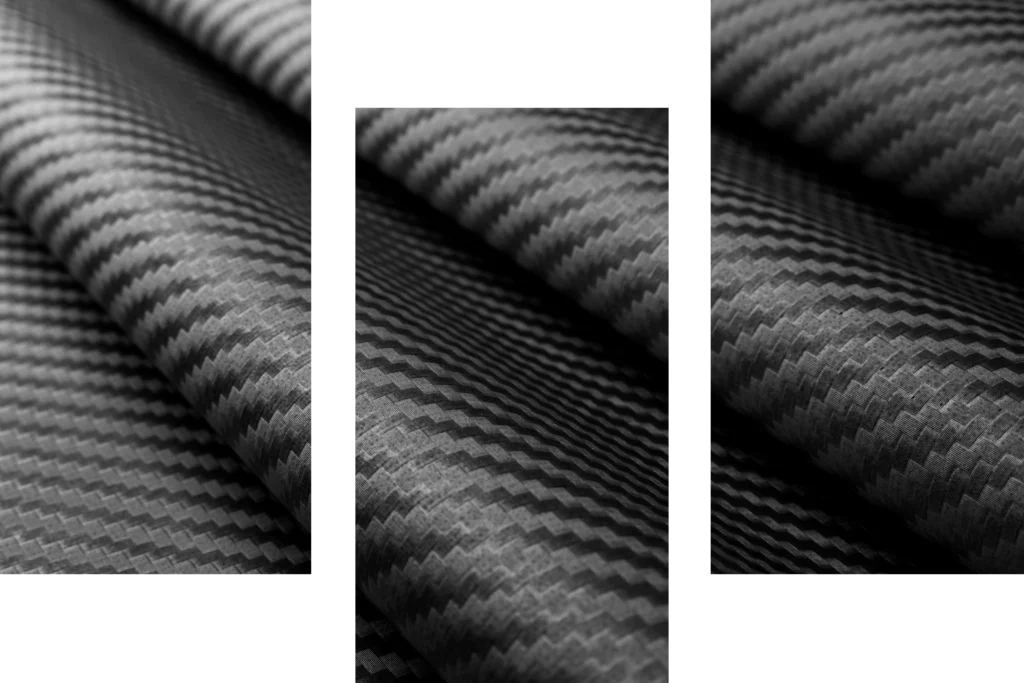

Twill Weave

Structural features: Each warp and weft yarn is interlaced more than twice to form a twill line.

-

Advantages:

-

Better flexibility than plain weave

-

Easier to fit complex curved surfaces

-

Appearance has a twill texture and strong decorative effect

-

-

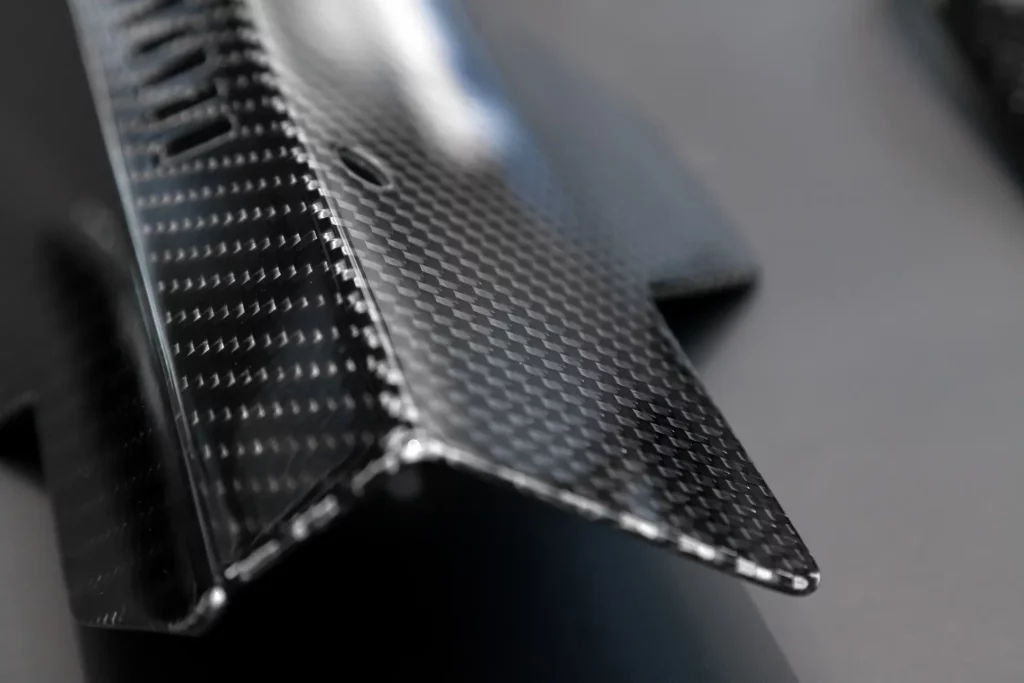

Applications: Automotive parts, sports equipment housings, aviation composite materials, etc.

Satin Weave

Structural features: fewer staggered points, smoother surface, higher gloss.

-

Common types: 5H, 8H satin, etc.

-

Advantages:

-

Good softness

-

More suitable for fitting complex geometric surfaces

-

Smooth surface, strong decorative effect

-

-

Applications: Advanced racing, aerospace, artwork composite surface.

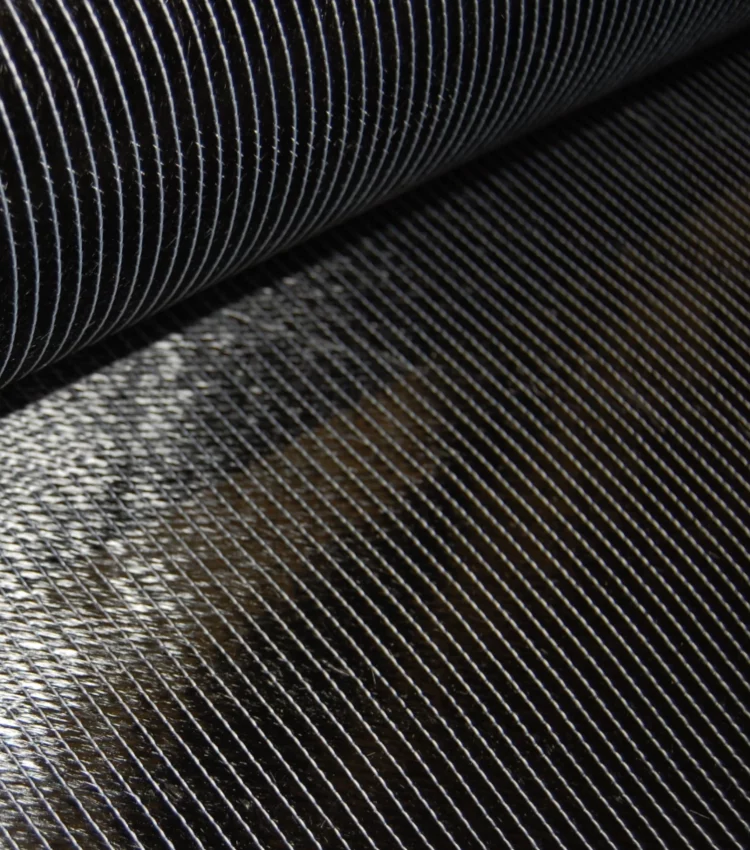

Multiaxial Fabrics

Structural features: non-traditional weaving, arranging multiple layers of fibers in different directions (such as 0°/±45°/90°) through a stitching process.

-

Advantages:

-

Better mechanical properties (multi-directional reinforcement)

-

No traditional staggered points, the fiber force is more direct

-

Good formability, suitable for large-sized structural parts

-

-

Application: large-sized structural parts such as wind turbine blades, ships, bridges, etc.

Flexible Carbon Fiber Fabrics for Advanced Applications

Actex’s expertise in composite fibers enables us to adapt fabric specifications to your exact project needs.

Customization

Our selection covers different weave styles, from basic plain, twill and satin patterns to special weaving techniques; customizable weights and widths to suit your manufacturing needs.

Technical Support

For any carbon fiber technical concerns—from initial inquiry through maintenance—our experts guarantee contact within 12 hours, ready to collaborate on a rapid and effective solution.

Efficient Delivery

We have no strict quantity requirements, 1 roll and 1000 rolls are delivered at the same standard. Your custom order can be delivered in as little as two weeks.

Why Choose Actex Carbon Fiber Solution?

Global Procurement Network

Select the finest carbon fiber raw material suppliers to guarantee stable supply. We offer a lead time as short as 7 days for the delivery of carbon fiber from our premium suppliers directly to your facility.

Solution on a Budget

At ACTEX, we are dedicated to supplying top-tier carbon fiber within your budget. Our objective is to function as your dependable outsourced purchasing department, delivering bespoke solutions designed to fulfill your project demands.

Strict Quality Control

Our meticulous quality control process includes rigorous testing of every batch, guaranteeing consistent product performance and dependability. To facilitate your regulatory adherence, we offer a complete portfolio of certifications.

Professional Advice

Boasting an average of 15+ years of experience, our composite fiber engineers provide bespoke solutions and extensive technical assistance. Having provided carbon fiber technical support to more than 200 clients, our reach continue to increase.

Let’s Talk About Your Project – We’re Here to Help