Carbon Fiber Sheets

Our carbon fiber sheets are made of high quality carbon fiber fabrics and high performance epoxy resin, achieving a perfect balance between strength, stiffness and ultra-light weight. We provide 0.2mm to 10mm thickness and support customized sizes, surface treatments and weaving methods to meet various application requirements.

- Home

- Carbon Fiber Sheets

Explore Actex Carbon Fiber Sheets

It seems we can't find what you're looking for.

Choose ACTEX for Carbon Fiber Sheets Where Aesthetics Meet Performance

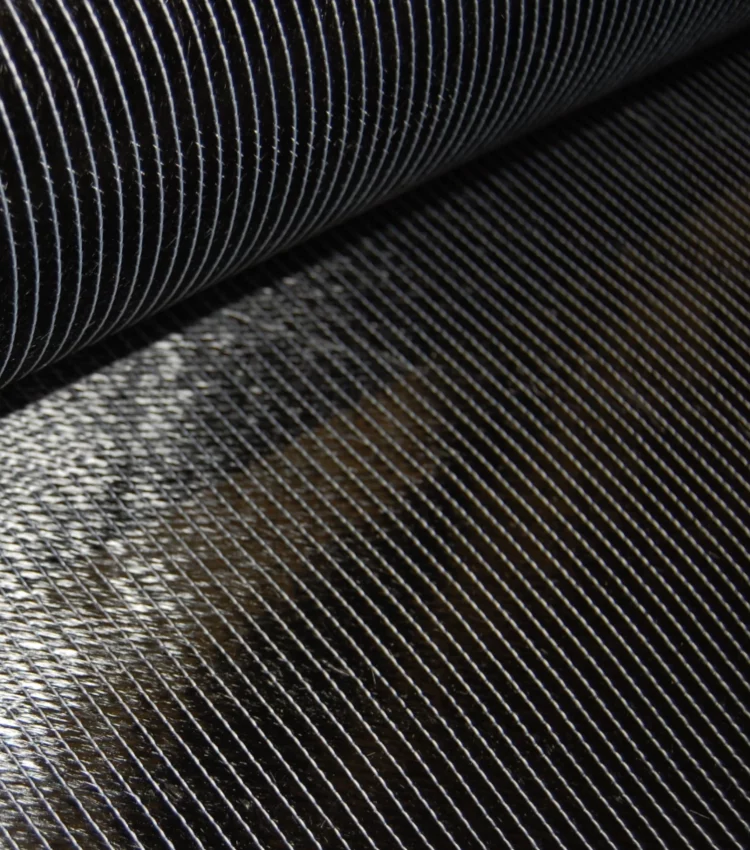

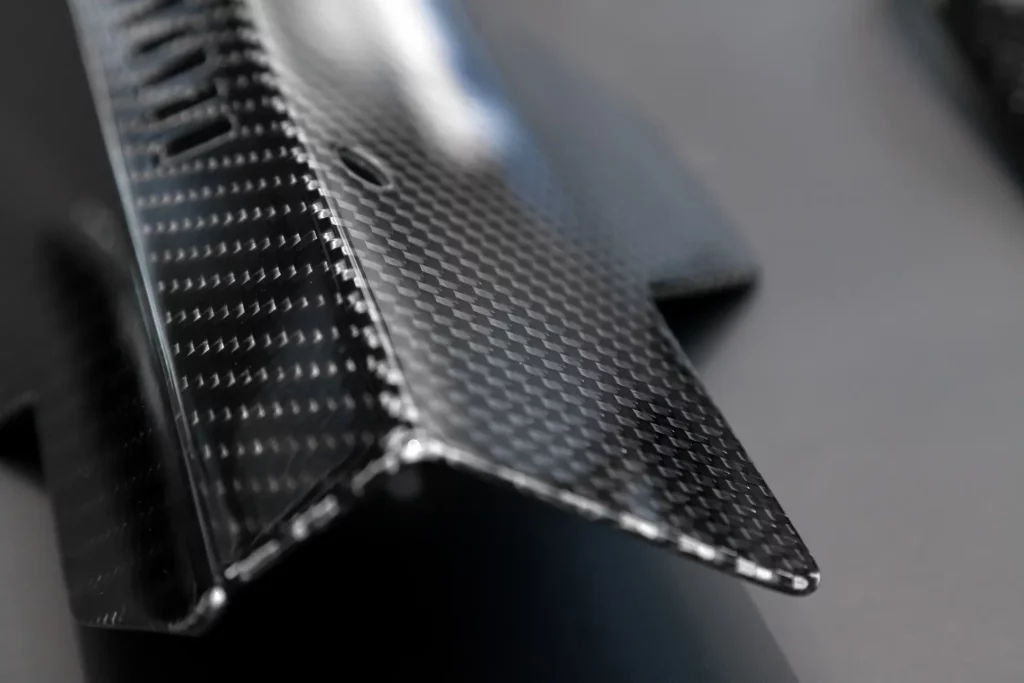

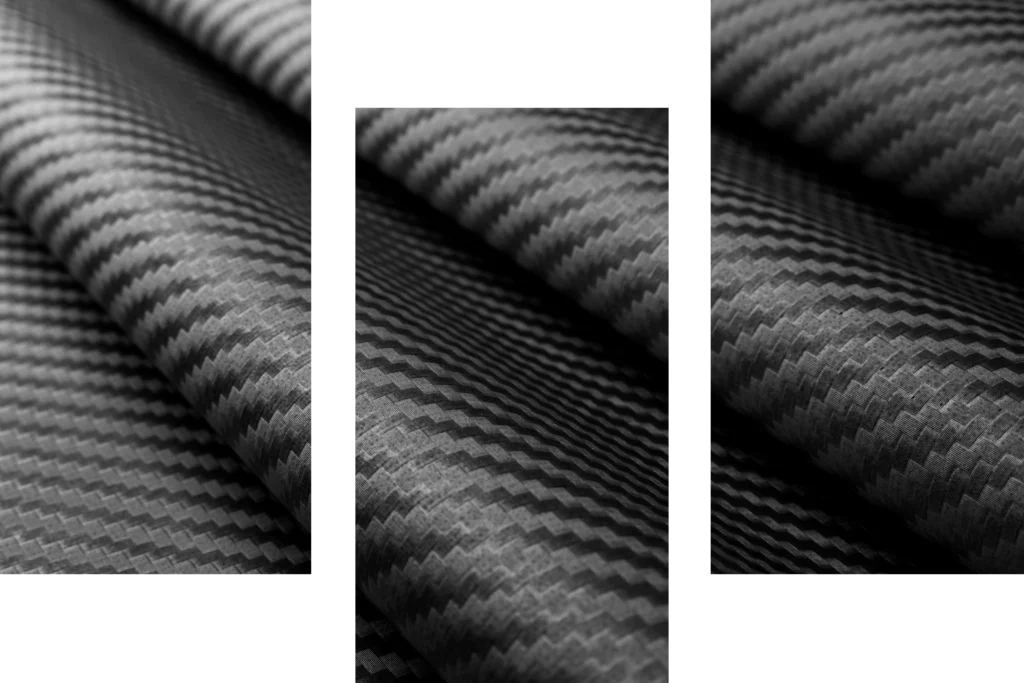

According to different surface treatments, Carbon Fiber Sheet can generally be divided into three categories, namely Glossy Surface, Matte Surface and Sanded Surface. Combining with different weaving methods can also achieve different pattern effects, improving structural performance while increasing aesthetics.

Glossy Surface

-

Features: Bright and transparent surface, the carbon fiber weaving texture is clearly visible.

-

Common uses: car panels, notebook shells, audio shells, drone shells, etc.

-

Recommended weaving combination: twill / satin

Matte Surface

-

Features: Low-reflective surface, more resistant to fingerprints, and a high-grade matte texture.

-

Common uses: Used in professional equipment, low-key appearance design or scenes that are sensitive to reflections, such as industrial structural parts, photographic equipment housings, military and police equipment, and sports equipment.

-

Recommended weave combination: twill / unidirectional fabric

Sanded Surface

-

Features: The surface is polished and suitable for subsequent bonding, spraying or laminating processes.

-

Common uses: Used for functional purposes such as structural parts, mold inserts, glued components, such as fixture bases, brackets, composite structural parts, etc.

-

Advantages: Strong adhesion and easy secondary processing.

Custom Carbon Fiber Sheets for High-Performance Demands

Actex’s expertise in composite fibers enables us to adapt specifications to your exact project needs.

Tailored Specifications

Adjust the weaving method, thickness and surface treatment according to your needs. Our standard options include 0.2mm – 30mm thickness, 4 standard weaving methods, and 3 surface treatment processes. We also provide more special process services.

Engineering Support

Whether you need help selecting the right braid material or verifying structural performance, our technical team can contact you within 12 hours to provide timely advice and custom solutions.

Quality Consistency

No MOQ limits—whether you need a single piece or bulk volume, your carbon fiber sheets will be delivered with the same attention to quality.

Why Choose Actex Carbon Fiber Solution?

Global Procurement Network

Select the finest carbon fiber raw material suppliers to guarantee stable supply. We offer a lead time as short as 7 days for the delivery of carbon fiber from our premium suppliers directly to your facility.

Solution on a Budget

At ACTEX, we are dedicated to supplying top-tier carbon fiber within your budget. Our objective is to function as your dependable outsourced purchasing department, delivering bespoke solutions designed to fulfill your project demands.

Strict Quality Control

Our meticulous quality control process includes rigorous testing of every batch, guaranteeing consistent product performance and dependability. To facilitate your regulatory adherence, we offer a complete portfolio of certifications.

Professional Advice

Boasting an average of 15+ years of experience, our composite fiber engineers provide bespoke solutions and extensive technical assistance. Having provided carbon fiber technical support to more than 200 clients, our reach continue to increase.

Let’s Talk About Your Project – We’re Here to Help