Carbon Fiber Yarn

Actex delivers carbon fiber yarns which have high strength and low mass and are durable in even the most challenging applications. We offer Toray T1000, M40 and M55, and T300, T700 in standard modulus. Since our global sourcing and quality control, we guarantee a steady supply of quality carbon fiber yarns that fulfill your manufacturing requirements.

- Home

- Carbon Fiber Yarn

Carbon Fiber Yarn Model Selection

Unlocking Carbon Fiber’s Full Potential Through Advanced Processing

As a transitional reinforcement matrix, carbon fiber yarn requires intermediate forming processes (such as wet winding, pultrusion, or thermoset molding) to achieve optimal performance.

At Actex, our diverse carbon fiber processing technologies meet your reinforcement needs for different application scenarios.

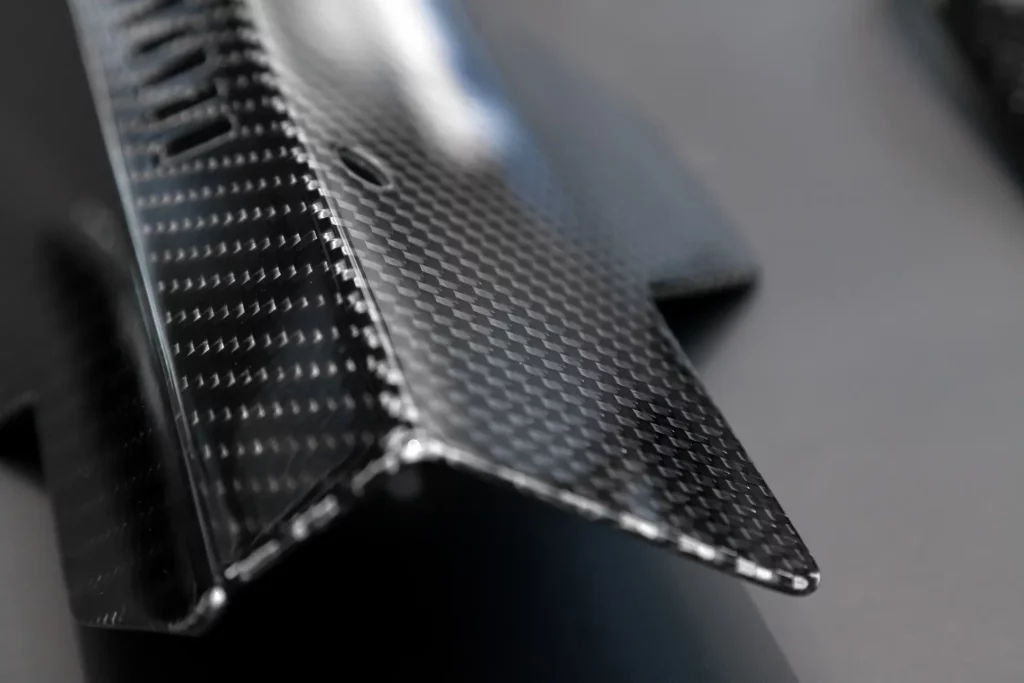

Weaving

Carbon Fiber Fabric woven by Plain Weave, Twill Weave and Satin Weave has a uniform surface and flexibility, and can be used in composite material manufacturing, such as aircraft, automobiles, wind turbine blades, etc.

Prepreg

Prepreg is formed by impregnating carbon fiber yarn with epoxy resin. It can be used to make high-strength composite materials in the fields of aerospace, automobiles and sporting goods.

Pultrusion

Pultruded carbon fiber yarn can be made into carbon fiber sheets, tubes and profiles, and used in construction, civil engineering, rail transportation, etc.

Injection Molding Reinforcement

Chopped carbon fiber yarn can be used as a plastic strengthening material to reinforce the strength and durability of automotive components and the casings of electronic products.

Filament Winding

Carbon fiber yarn can be used to manufacture high-strength composite pipes, gas storage tanks, such as high-pressure hydrogen cylinders, spacecraft fuel tanks, etc.

Adaptable Carbon Fiber Yarns for Advanced Applications

Actex’s composite fiber expertise enables us to tailor fiber specifications to your exact needs.

Specification

different fiber diameters (such as 1K, 3K, 6K, 12K, 24K, etc.) to meet various manufacturing needs.

Customized Solutions

adjust specifications, performance parameters, etc. according to your needs.

Packaging and Delivery

support bulk purchases, and we promise fast delivery.

Why Choose Actex Carbon Fiber Solution?

Global Procurement Network

Select the finest carbon fiber raw material suppliers to guarantee stable supply. We offer a lead time as short as 7 days for the delivery of carbon fiber from our premium suppliers directly to your facility.

Solution on a Budget

At ACTEX, we are dedicated to supplying top-tier carbon fiber within your budget. Our objective is to function as your dependable outsourced purchasing department, delivering bespoke solutions designed to fulfill your project demands.

Strict Quality Control

Our meticulous quality control process includes rigorous testing of every batch, guaranteeing consistent product performance and dependability. To facilitate your regulatory adherence, we offer a complete portfolio of certifications.

Professional Advice

Boasting an average of 15+ years of experience, our composite fiber engineers provide bespoke solutions and extensive technical assistance. Having provided carbon fiber technical support to more than 200 clients, our reach continue to increase.

Let’s Talk About Your Project – We’re Here to Help